Hoerbiger hält flüchtige Emissionen unter Kontrolle

Systemlösung zur Kontrolle von Emissionen: Drei Produktklassen, geeignet für unterschiedliche Kundenbedürfnisse

Stickstoffspülsysteme sind keine neue Erfindung. Die Herausforderung bestand aber darin, Hoerbiger und seinen Kunden die Einführung dieser Systeme zu erleichtern. Die branchenübliche Praxis ist die Lieferung maßgeschneiderter Paneele, die speziell nach den Spezifikationen des Kunden konstruiert und gebaut werden, was den gesamten Prozess sehr zeit- und kostenintensiv macht.

Im Gegensatz dazu wollte Hoerbiger den Prozess vereinfachen, so dass er fast so einfach ist wie die Auswahl aus einem Katalog; dazu mussten sie die maßgefertigten Paneele zugunsten eines modularen, standardisierten Designs aufgeben. Um zu viele verschiedene Optionen zu vermeiden, wurden 3 Produktklassen geschaffen, die für unterschiedliche Kundenbedürfnisse geeignet sind.

Emission control panel by Hoerbiger | Swagelok Austria from Swagelok CH/AT on Vimeo.

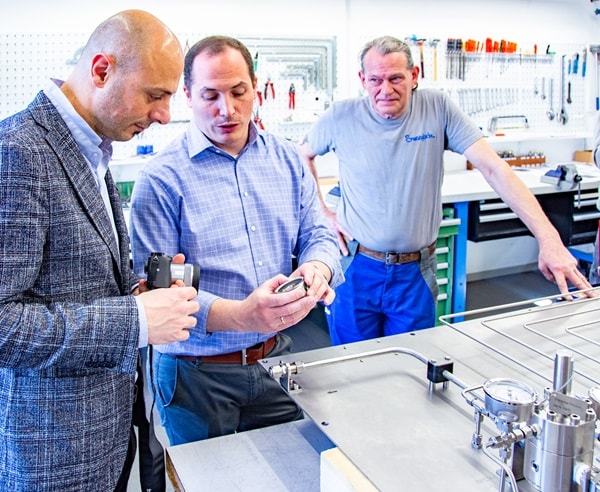

Qualitätskontrolle und Abnahme der Baugruppe ( vlnr.: B. Pratelli (Hoerbiger), C. Gruber, M. Furter (Swagelok Austria).

Interview mit Herr Pratelli von Hoerbiger in Englisch:

Swagelok: Mr. Pratelli, can you please briefly introduce the company Hoerbiger and its areas of business?

Guido Pratelli: Hoerbiger is a multinational company with headquarter in Switzerland. We are active in several industry segments such as oil & gas, automotive and e-mobility, and many more.

Our Compression Technology division supplies components for gas compressors that are typically found in refineries, petrochemical plants, natural gas pipelines and processing plants, food industries etc.

We are market leaders for valves, capacity control systems, piston and rod seals and we are present almost everywhere in the world. Our production for EMEA is headquarterd in Vienna, Austria.

Guido Pratelli: Reciprocating compressors operate with toxic, flammable, explosive and corrosive gases all the time. Avoiding leakage of these gases in the atmosphere is important for safeguarding the health of the operators as well as the environment: this is accomplished mainly by the rod packing. Unfortunately, the seals in a rod packing are never perfectly tight. This causes leakages that, if left unattended, will generate a cloud of gas in the area around the compressor.

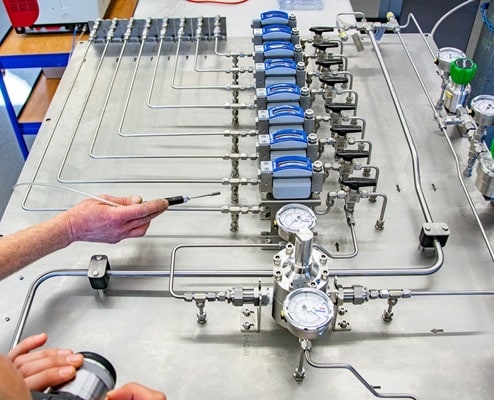

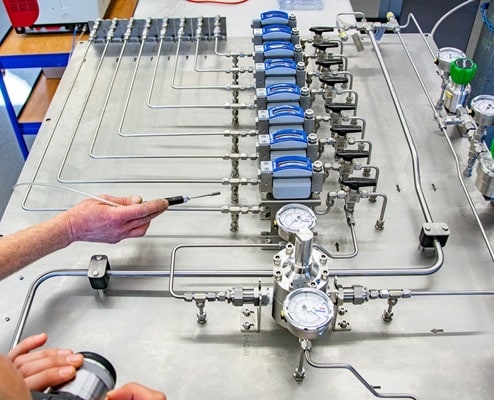

As explained, this is a safety hazard for the operators working around the machine, but can also be an issue in terms of machine integrity and a source of pollution and greenhouse gas emissions. We wanted to tackle all of these issues and designed a panel which creates a nitrogen barrier in the packing, that eliminates all uncontrolled emissions. Now, all the leakage from the rod packing is contained in a closed line, which carries the gas away and sends it to an appropriate disposal system.

The panel also has 2 pressure relief valves that protect both the rod packing and the compressor casing from over pressurization. This eliminates the possibility of damaged equipment due to failure, malfunction or wrong regulation.

As a result, the compressor operation is guaranteed to stay safe and clean in all circumstances.

Coupled with a flare system, our emission control panels guarantees more than 95% abatement of greenhouse gas emissions. As a matter of fact, hydrocarbons are much less harmful for the climate when combusted, rather than released directly in the air. Our panels are designed to work with virtually any compressor in any industrial environment, including offshore platforms.

Swagelok: Were there any challenges with this project and how was Swagelok able to support you?

Guido Pratelli: Nitrogen purge systems are not a new invention, but the challenge was to make it easy for Hoerbiger and its customers to adopt these systems. The industry standard practice is to supply custom made panels, specially engineered and built according to customer specifications, which makes the whole process very time and cost intensive.

On the contrary, we wanted to simplify the process, making it almost as easy as to choose from a catalogue; to do so, we had to abandon custom made panels in favor of a modular, standardized design. To avoid too many different options, we created 3 product classes which are suitable for different customer needs.

We started with putting together regulators, instruments, tubing and fittings, and quickly realized that to have the best possible design, we needed to know more about how all these components work. Swagelok helped us to understand the inner workings of each and every component, allowing us to make the right design choices. Now, we know intimately each single piece of the panel and understand how everything is integrated and work together in the assembled product.

Swagelok: Clemens Gruber, you are the Sales Engineer on this project. Can you talk about your experiences with Hoerbiger and what your milestones/highlight were?

Clemens Gruber: Our business relationship has existed for several years, but we started this specific project together in 2019.

For me, one of the highlights of the project was the development of a construction structure that, based on functionality and safety, offers a coordinated coverage of customer requirements with a standard model kit.

Swagelok: What did you appreciate most about the collaboration with Swagelok?

Guido Pratelli: I value the easy, straightforward communication with our counterparts. On Technical level, our partners are capable and everyone knows the products intimately.

With the in-house tests at the Swagelok premises, we are now closing the loop, making sure that the panel can be installed in a «plug and play» fashion. As the panels are fully tested and factory regulated, it is much less of a hassle for customer to install them on site. It is a big plus that for the customer on site the commissioning is downsized to a minimum.

Swagelok: Thanks a lot Guido Pratelli for giving us an insight into the Hoerbiger Emission Control Panel Project which started with Swagelok in Northamerica, was adapted for the market in EMEA 2022 and will be available in Asia/Pacific area soon.

Das Thema Baugruppen & Anlagebau interessiert Sie? Bei uns bekommen Sie alles aus einer Hand.

Ich will mehr darüber wissen

Sie haben Fragen zu einem Projekt oder sind interessiert an Swagelok Produkten?

Wir freuen uns auf Ihre Kontaktaufnahme.

info@aa-solutions.at | +43 2236 677079